2017: FIRST® STEAMWORKS

The 2017 season brought a series of great experiences and challenges for both members and coaches. After returning from a trip to China, our team was met with a challenging and multi-faceted game that required much prioritizing in order to successfully complete all tasks. Our drive base and frame were CADed by students, a definite feat for our team. We embraced the game theme by making steam punk daisy headbands, which were sported at each competition. Also joining us was Superintendent Crisfield and President of FIRST® Don Bossi, who both visited our pit at different competitions. Though the game presented several challenges, our team pulled through and had a great season, with plenty of learning opportunities.

- FIRST® Mid-Atlantic Hatboro-Horsham District Competition: Innovation in Control Award

- FIRST® Mid-Atlantic Hatboro-Horsham District Competition: #2 Seed

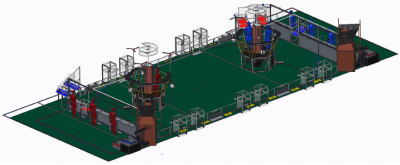

2017 Robot, “Miss Daisy XVI”

Overall Robot

- 120 pounds

- 24″ tall, 40″ wide, 36″ long

- Low center of gravity

Drive

- (6) 4″ VexPro VersaWheels

- (4) CIM VexPro WCP Dual-Speed Gearbox: 9/17 fps

- Capable of high speeds and pushing

- Custom sheet-metal bellypan designed to reinforce robot and provide organized electronics mounting

Gear Manipulator

- Lexan-hinged intake flap powered by (2) servos with aluminum 2-bar linkages

- Lexan-hinged backplate braced by dual pistons to allow balls to roll into hopper

- Plastic angled L-bracket pieces to center intake gears

- Hinged bottom plate actuated by piston

Climber

- Hooked Velcro wrapped around metal tubing

- CIM motor through 35:1 VersaPlanetary turns shaft via chain run

- “Comb” constructed from bent 1/4” thick aluminum maintains rope alignment

Ball Intake

- 21” long double rollers connected via rubber belting

- Powered by (1) 775pro motor contacting steel bevel gears via 5:1 reduction

- Can collect balls from the floor, pulling them upward against a backplate and feeding into hopper

Hopper, Agitator, Turret, Shooter

- Hopper: passive materials such as Lexan and Coroplast allowing for maximimum ball capacity; can hold 40 to 45 balls

- Agitator: shaft with extruding passive materials to align balls into vertical feed; powered by a 775pro with a 5:1 reduction

- Turret: powered by 775pro with a 50:1 reduction; gives 360 degree access for shooting position

- Shooter: custom acrylic hood powered by CIM with a 11:8 reduction; (2) 4” Colson wheels; (2) 6” blue BaneBots wheels

Sensors

- Turret: hard limit switches, CTRE Magnetic encoder, Axis Network Camera

- Gear Manipulator: CTRE Magnetic encoder, hard limit switches

- Drive: Greyhill 256 CPR optical encoders, NavX MXP 9 Axis IMU

Software

- Java robot code with “DaisyCV” vision processing

- Closed loop PID control is handled by Talon SRX in conjunction with CTRE Magnetic encoders to control turret position and flywheel velocity

- Preplanned trajectories for each autonomous mode

- Sophisticated goal tracking to ensure the boiler’s position is always known relative to robot position and heading

Photos

- Kickoff & Brainstorming

- Build Season

- Hatboro-Horsham District Competition

- Springside-Chestnut Hill District Competition

- Shady Grove Elementary School Science Night

- FIRST® Mid-Atlantic District Championship

- World Championship

- End-of Year Banquet

- Pike Fest Community Demonstration

- Ramp Riot

- FTC Qualifying Tournament

- Team 341 Night

Videos

2017 Game Challenge, FIRST® STEAMWORKS

This years FIRST® Robotics Competition game invites two adventurers’ clubs, in an era where steam power reigns, to prepare their airships for a long distance race. Robots collect fuel (balls) and score it in their boiler via high and low efficiency goals. Boilers turn fuel into steam pressure which is stored in the steam tank on their airship – but it takes more fuel in the low efficiency goal to build steam than the high efficiency goal. Robots deliver gears to pilots on their airship for installation. Once the gear train is complete, they turn the crank to start the rotor. Robots must latch on to their airship before launch (the end of the match) by ascending their ropes to signal that they’re ready for takeoff.