Over the first four weeks of build season, we have become incredibly good at tidying up. Sure, we throw some pieces of metal together and mess around with wires, but boy can we organize a space. We’ve got a lot of stuff–probably too much, but you don’t need to know that (it’s not hoarding if it’s useful!) Between our seemingly dozens, (maybe thousands? I don’t know, I’m just one media kid) of subsystems, the materials that accumulate on the assembly room tables are truly a sight to behold. I don’t even know what half of it is called, but it’s obviously pretty important considering how much space it takes up. Yet, this space is squeaky clean every Sunday at 5 pm. This speed cleaning has become incredibly important, especially at the moment, because sponsors are sending us our parts!

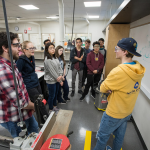

As more parts come in, there is more work to be done, and more things to put away. The hours upon hours that were put into CADs are finally coming to fruition, and rookies get to hold their hard work for the first time. The assembly room is crowded with students as they assemble the drivebase. But it’s not all fun and games in the shop. Yeah, drivebase assembly is super fun, but you know what else really gets the blood pumping? Disassembling gearboxes. Coach Adam has been teaching rookies to take apart last year’s gearboxes to take out the power take-offs, or PTOs. These little things take a whole bunch of power and send it to a specific part of the robot. Coach Adam says it’s a good exercise, but I think it’s a special kind of punishment for not wearing safety glasses.

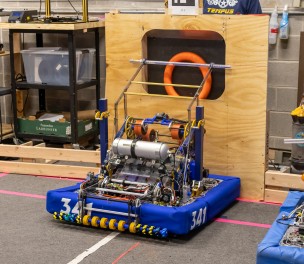

The gamepiece manipulator subteams have been making progress as well as they await the arrival of their parts. The cargo passthrough has a fun and fresh design, which was prototyped and tested on Saturday morning. As it turns out, with the help of a bunch of zipties and stretchy cords, a group of children can do some wonderful things. This design is being CADed as I type these very words. As for the hatch subteam, they’re continuing to work on their scoop mechanism for picking up the hatch panel. I’ve seen lots of spinning 3D structures on screens, so it’s safe to say they are CADing.

A portion of the programming team has been writing code for the various subsystems of the robot. This code will help the robot to do, well, everything. Each subsystem has code that goes along with it, and without it, we’d be professional hunk of metal makers. Still, some programming team members are still being chased by a previous year’s drivebase. They’re usually carrying a piece of cardboard with some reflective tape on it. They say they’re tweaking the distance by which the robot’s vision code is effective, but I’d like to think they’re training for the Boston marathon.

A portion of the programming team has been writing code for the various subsystems of the robot. This code will help the robot to do, well, everything. Each subsystem has code that goes along with it, and without it, we’d be professional hunk of metal makers. Still, some programming team members are still being chased by a previous year’s drivebase. They’re usually carrying a piece of cardboard with some reflective tape on it. They say they’re tweaking the distance by which the robot’s vision code is effective, but I’d like to think they’re training for the Boston marathon.

As we begin to assemble the robot, we’ve been channeling our inner Marie Kondo at the end of each day. If we’ve split a piece of wood, we throw it out. If a prototype is bad, we don’t hang onto it. We can always make a new one, which is a lot less painful than dealing with it all competition season. Never forget to ask yourself, “does this spark joy?”