Written by Vivian H., Matthew D., and Hemish M.

During Kickoff weekend, we gathered together unable to contain our excitement as the game was announced. This year’s game, Crescendo, consists of a ring-shaped game piece “Note” that is to be scored in an open goal (the “Speaker” or “Amp”) or an elevated goal with a flap (the “Trap”). At the end of the game, alliances race to hang on chains surrounding the Stage apparatus on the field. Human players can also throw a Note and attempt to score onto a pole-like goal in order to “Spotlight” their robot during the endgame.

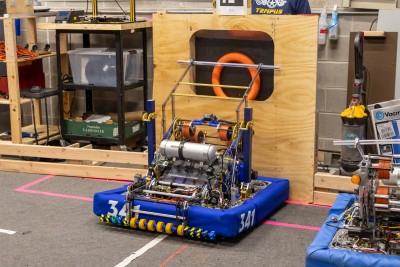

After seeing the game, we got together and brainstormed strategies and robot architecture. Within the first few days of kickoff, the KitBot was created, a robot with basic scoring functionality to give the programmers a robot to work with. With that, we were able to start creating our autonomous paths and auto-alignment functionality with vision.

With a basic strategic framework guiding the growth of the mechanical subteam, we got to work. We prototyped different intakes, shooters, climbers, and amp/trap scoring mechanisms. Learning interactions with the note was a difficult challenge for us, since many members of our team were used to more spherical game pieces.

The first step was constructing the drivebase. Our drivebase subsystem worked furiously for the first week of build season to create a sturdy base that would allow all of the dimensional and mechanical constraints of our robot to be fulfilled.

For the intake subsystem, we started out with three initial intake prototypes: a double roller, vectoring wheels and roller, and a beaver tail intake. The beaver tail prototype consisted of belts powered by a single drill meant to grapple onto the note piece. After a couple trials, however, we discontinued this prototype. The double roller originally consisted of a single set of rollers, then two sets of rollers. Given that this was an effective “final funnel” of the game piece, we determined this to be our final under-the-bumper-uptake. The vectoring wheels and roller consisted of a wheel roller with parallel belts. This eventually evolved into our swerve belt wraps – belts that span the outside of our swerves and fully encompass our drive base to provide greater vectoring coverage.

For the amp subsystem, we developed two major contested prototypes. The first one was the amp fixed angle arm meant to directly shoot the note into the amp. Given limited shooter angle flexibility and general trial inconsistencies, this was abandoned. The second design included a virtual 4-bar. This is an arm that essentially “dampens” the note as it is shot. The benefits of this prototype included its functionality in collaboration with the shooter.

For the conveyer, we stuck with a roller idea. We began with a four roller system and then added a polycarbonate plate, extended side guards, and areas for electrical mounting.

In the shooter subsystem, we had three main prototypes: a horizontal, vertical, and high-compression horizontal design. After prototyping the horizontal designs versus the vertical designs, we determined that the vertical design’s benefits outweighed the horizontal. The vertical shooter provided us with greater power, bettering packaging in the robot, and the same ability to apply spin on the note.

One of the largest challenges to our team mechanically included constructing the climber. We began with wall climb and elevator climb prototypes. Ideally, these designs would allow us to potentially score “Trap.” But given the resources and lack of control we identified, we eventually narrowed our focus down to a simpler, inverted telescoping climber design. As a more lightweight design, we shifted our focus from the trap to optimizing our cycling time.

Though there were setbacks on the trap, amp, and climber that led to a few important strategic and mechanical pivots, we were able to quickly resolve these issues and still meet most of our strategic requirements for the season. We also created the beta bot with our potential final robot mechanisms to test for any issues without designs, and allowing the programmers to start programming while mechanical was building the competition robot.

Our programming team has worked hard developing software to ensure easy and accurate functioning of our robot and autonomous paths. A notable feature this year of our robot includes our adjustable shooter hood. This utilizes robot pose estimation with AprilTags to determine correct angling for the hood into the “Speaker.” The subteam ran calculations through an interpolation table with linear regression and trigonometry to enable long-distance targeting – critical in ensuring speed and accuracy.

Our electrical subteam focused on mounting key components onto both the initial Kitbot and actual beta and competition robots. This included wiring the drivebase and eventual robot pneumatic and electrical components after complete assembly.

Throughout the season, our marketing and outreach team has been working tirelessly on STEM Sprouts. We began our brand-new STEM curriculum for elementary-aged students. Consisting of monthly evening sessions, activities so far have included building catapults, making elephant toothpaste, and conducting egg drops.

Our media team has also been hard at work: creating videos like bi-weekly recaps, our impact award video, and our 2024 robot reveal.

From the perspective of co-captains, we are really proud of our team. By taking a step back and seeing our rookies learn, seeing our robot iterating, and seeing the positive impact we have made on our community, it is easy to recognize our accomplishments this build season. Although the build season may be officially over, we are still building on our robot and outreach. We will never stop growing.

Thank you to our sponsors: the Cleveland-Cliffs Foundation, Comcast NBCUniversal, ASTM International, the Kiwanis Club of Ambler, BOEING, TE Connectivity, Lockheed Martin, CAES, CCC, PennState Great Valley, West Coast Products, Minuteman Press Ambler, Welding Technologies, Wissahickon Education Alliance, Solidworks, Wissahickon School District, Denney Electric Supply, Onshape, and Wissahickon Educational Opportunities Foundation.

Be sure to continue watching us blossom through our competition season.