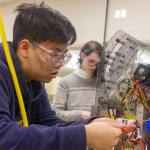

It’s been quite the time here in our shop. Last week, we received some unfortunate news that our drivebase would be arriving from our manufacturing sponsor a bit later than we expected. This was not nearly as heartbreaking as the time we ran out of the chocolate twinkies from our snack stash, so we recovered quickly. We reworked our build schedule, and planned to do as much as we could before the drivebase arrived. Upon receiving our components, we got to work riveting and wiring it. We were a little behind in comparison to previous build seasons, but bag day is no more, so we weren’t too concerned.

It’s been quite the time here in our shop. Last week, we received some unfortunate news that our drivebase would be arriving from our manufacturing sponsor a bit later than we expected. This was not nearly as heartbreaking as the time we ran out of the chocolate twinkies from our snack stash, so we recovered quickly. We reworked our build schedule, and planned to do as much as we could before the drivebase arrived. Upon receiving our components, we got to work riveting and wiring it. We were a little behind in comparison to previous build seasons, but bag day is no more, so we weren’t too concerned.

On Saturday morning, Miss Daisy XVIV took her first steps. Except the Xbox controller’s joysticks were reversed, so we nullified her first steps and acted like they never happened. Then she had her second first steps, and we burnt rubber all over the floor and spent the next twenty minutes scrubbing it off. Then she had her third first steps, and those were pretty good. The drivebase was pretty zippy, so we tried to attach some weight to better simulate a full robot. Many students volunteered, but apparently that was “unsafe”.

Other subsystems have been progressing quite nicely, though some are starting to feel the heat. Our  hanging group has been working to construct a mechanism that extends to a bar in the middle of the field. They’ve gone through several iterations of 3D printed parts that could just as easily be replaced with a glob of Elmer’s glue, but that idea was ruthlessly shot down. The power cell manipulator subsystems have also been making strides. Several groups of students have been developing final versions of their mechanisms, which will be going on the robot soon. Some people are calling for “drop tests” of each mechanism, but this has been vetoed by the build team. There is no place on our robot for a fragile mechanism, and dropping each design seems like a good way to prevent this.

hanging group has been working to construct a mechanism that extends to a bar in the middle of the field. They’ve gone through several iterations of 3D printed parts that could just as easily be replaced with a glob of Elmer’s glue, but that idea was ruthlessly shot down. The power cell manipulator subsystems have also been making strides. Several groups of students have been developing final versions of their mechanisms, which will be going on the robot soon. Some people are calling for “drop tests” of each mechanism, but this has been vetoed by the build team. There is no place on our robot for a fragile mechanism, and dropping each design seems like a good way to prevent this.

Our programmers are reaching the end of the work they can do before our robot is completed. They’ve been working on the code for our ball path mechanisms, and testing on our homemade field parts.Through this, they’ve been able to improve our robot’s accuracy into the goals. With our robot coming together, our team has focused on making this robot the best it can be. We’ve paid close attention to each detail, and hope to have a fully constructed robot within the next week. In the meantime, we’ll be throwing it off of the third floor of our school to see if it sticks the landing.